This great Trumpf TruBend 7036 Bending Machine low hours is unfortunately already Sold.

Discover further Metalworking » Sheet Metal Working » Press Brakes machinery, or Contact us for further help.

Description:

This great Trumpf TruBend 7036 Bending Machine low hours is unfortunately already Sold.

Discover further Metalworking » Sheet Metal Working » Press Brakes machinery, or Contact us for further help.

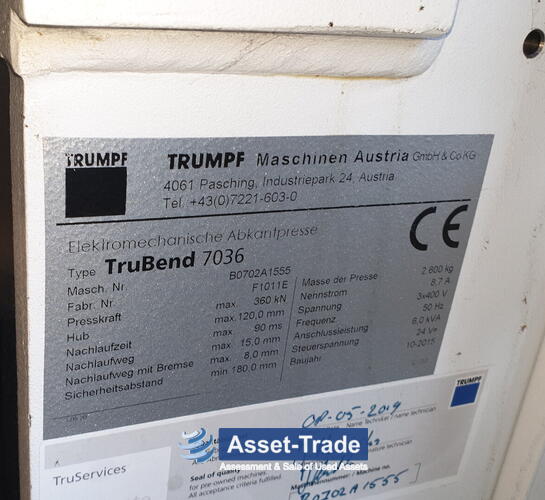

Used Trumpf TruBend 7036 CNC Bending Machine with 6 Axis for Sale

Build 10/2015 Operation Hours :ON 8352h / running time 619h

Sold Build 02/2011 Operating Hours : 19463 h / 2064 h

Bought in first class condition in 2019 overhauled by Trumpf!!!

AMADA Toolholder !! Wila only with Adapter

Technical data:

- Tonnage approx.: 360 kN

- Bending length approx.: 1020 mm

- Stroke Max.: 120 mm

- Distance between side frames approx.: 932 mm

- Eff. open height approx.: 300 mm

- Rapid speed: 220mm/s

- Max. working speed. 10-25 mm/s

- Space requirement approx.: 1805 x 1330 x 2380 mm

-

Electrical connected load approx.: 5 kVA

Standard equipment machine

- Stable machine frame

- Press beam

- Highly dynamic, electromech. Direct drive (torque motor)

- Inductive length measuring system with temperature compensation

- Control cabinet air conditioning

- Ergonomic machine design Fence system

- Backgauge system 3-axis X1, R1, Z1-axis Tool clamping

- Upper tool holder, self-centering, manual clamping

- Lower tool holder, manual clamping, hardened

Control system

- TRUMPF TASC 6000 integrated - SW Version 4.6.4.0

- Numerical workshop programming

- Windows XPe (embedded), Pentium M with 1.1 GHz clock frequency

- 1 GB RAM memory

- 15-inch touch screen

- Network capable

- Teleservice via modem

Safety

- Side hinged safety doors

- Rear safety cover

- 2-button foot switch, for standing and seated operation

- CE marking

Advanced features Machine

- Ergonomics package

- Backgauge: 6-axis backgauge (X1, X2, R1, R2, Z1 and Z2 axes)

- Tool clamping: AMADA tooling system

- Control : Graphic shop programming

- Operation:

- Rear work area lighting

- Bend line laser

- Safety: BendGuard

Trumpf 7036 CNC press brakes are one of the fastest press brake machines in the world designed specifically for CNC bending small sheet metal work components and assemblies. These small format CNC press brakes offer not only fast manufacturing bending speeds through their twin electric motor operation but quick set up times enabling small batches of sheet metal work to be manufactured just as efficiently as larger batches. Accuracy and efficiency are increased through the use of a 6-axis CNC back gauge system allowing the most complicated sheet metal work to be bent in one machine set-up and processing cycle repeatably and without delay.

TRUMPF bending machines represent a wealth of experience and pioneering innovation. The extensive portfolio includes machines for die and panel bending technologies as well as large format bending machines and fully automated solutions. There is a wide range of options available for each bending technology to suit your specific application. Use TruBend machines to produce simple and complex parts in any format precisely and cost-effectively. You always benefit from high-quality parts, increased flexibility, innovative tools, sophisticated automation solutions and intelligent software all from a single source. We focus on operability and ergonomics to ensure the machine supports operators in their work.