This great DOOSAN HM 800 Horizontal Machine Center with 2 Pallets is unfortunately already Sold.

Discover further Metalworking » Machine Centers » Horizontal Machine Center machinery, or Contact us for further help.

-

Media File

Machine Details:

Technical Details:

-

Control:

-

Spindle Speed:6.000 rpm

-

Tool Holder:

-

Tool Capacity:90 x

-

X-Axis:1.250 mm

-

Y-Axis:1.000mm

-

Z-Axis:1.000 mm

Description:

This great DOOSAN HM 800 Horizontal Machine Center with 2 Pallets is unfortunately already Sold.

Discover further Metalworking » Machine Centers » Horizontal Machine Center machinery, or Contact us for further help.

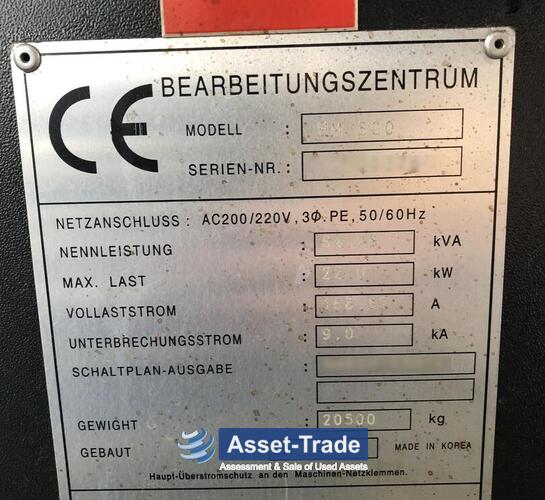

Used DOOSAN ACE – HM 800 Horizontal Machine Center

Control type: FANUC 18 - IM Macro

Technical data:

- Travels

- X axis: 1250 mm (49.2")

- Y axis: 1000 mm (39.4" )

- Z axis: 1000 mm (39.4")

- Rapid traverse rates X/Y/Z: 24m/s

- Cutting feed rates (X/Y/Z) : 12m/s

- Spindle

- Speed range : 20 - 6000 rpm

- Drive power: 18,5 / 22KW

- Gear stages: 3x

- Pallet

- Table size: 800 x 800mm

- Number of pallets: 2x 800x800 mm (31.5")

- Pallet indexing: 1 degree

- Maximum pallet load: 1600 kg (3,520 lbs)

- Pallet change time: 29 seconds

- Tooling

- Tool taper: A50, DIN 69871 B

- Tool length max. : 550 mm (5.3")

- Tool Ø max. : 250 mm (9.8") / with free adjacent space

- Tool weight max. : 25 kg (55 Lbs)

- Time from tool to tool : 2.5 seconds

- Number of magazine positions: 90 x pieces (automatic two-arm tool changer)

- Max workpiece height: 1200 mm

- Package tool offsets: 200

- Paper belt filter Exhaust system Schanier belt chip conveyor

- Main unit dimensions LxWxH: 3556mm x 6248 x 3229 mm / 140.00" x 246.00" x 127.00"

Machine ran 70% of the time in 2 shifts in 14 years.

Advantage of DOOSAN HM Series Horizontal Machining Centers

With close to 2,590 ft-lbs of spindle torque and plenty of pallet size to spare, Doosan’s HM Series is a horizontal beast that brings the value.

6,000 RPM spindle in the HM Series.

The term “heavy duty” is thrown around a lot in this industry. But here at Doosan, it doesn’t get much more heavy duty than the HM series. The gear-driven spindle eats heavier cutting requirements for breakfast, lunch and dinner.

How the HM Series handles heat buildup.

If heat buildup is not controlled, you can overheat the spindle in a hurry. Thankfully, the HM Series is equipped with spindle cooling that minimizes thermal error during extended heavy cutting. Wear and tear is minimized, and you stay cool as a cucumber.