This great CME - FS-1 CNC Bedtype Milling Machine is unfortunately already Sold.

Discover further Metalworking » Milling Machines » Bed Type Milling Machine machinery, or Contact us for further help.

Machine Details:

Technical Details:

-

Control:

-

Spindle Speed:3.000 rpm

-

Tool Holder:

-

X-Axis:1.400 mm

-

Y-Axis:1.000mm

-

Z-Axis:1.000 mm

Description:

This great CME - FS-1 CNC Bedtype Milling Machine is unfortunately already Sold.

Discover further Metalworking » Milling Machines » Bed Type Milling Machine machinery, or Contact us for further help.

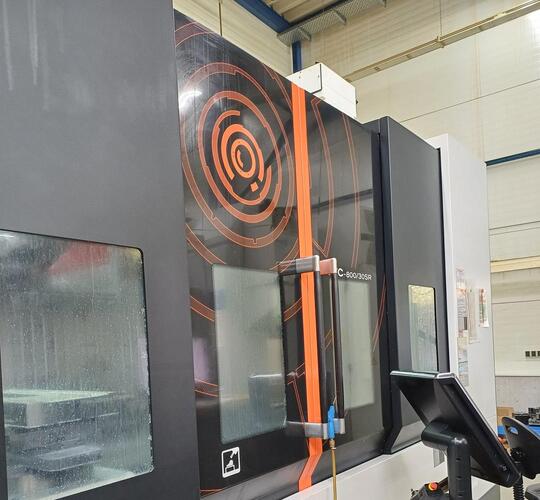

Used CME FS-1 CNC Bedtype Milling Machine

CNC Heidenhain TNC 410 Control

Technical Data

- Travels

- X-Axis : 1400 mm

- Y-Axis : 1000 mm

- Z-Axis : 1000 mm

- Table Size: 1600x1000 mm

- Max. Weight On Table: 4.500 kg

- Motor Power: 27 kW

- Spindle Taper: ISO-50 / DIN 69871

- Spindle Speed Range: 50~3000 rpm

- Rapid Traverse Speed in 3 Axes: 20 m/min

- Positioning Accuracy in 3 Axes: ±0.005 mm

- Repeatability Accuracy in 3 Axes: ±0.005 mm

- Weight: 13.000 kg

- Digital Motors

- Drives Linear Guideways

- Linear Guide Motionblocks ix X/Z/Y axe

- Universal Milling Head

- Thermal Compensation

- CE Norms

- Complete Coolant System Automatic Centralised Lubrication Hydraulic Compensation

- HR-140 Haidenhain Portable Hand Wheel Horizontal / Vertical Positioning

- Semi Automatic Milling Head

- 15 bar Cooling Through Spindle

This machine is in Auction which ends on 31 Oct 2021 from 12:00 AM CEST

https://auctions.maynards.com/auction-020/itemDetails/4392/547385

The FS Series range is the result of years of work and improvement, developing a product of great structural rigidity. It is a heavy, oversized machine to ensure the best possible response in limit working conditions.The different FS Series models offer a great range of working capabilities thanks to their different itineraries, which enable the machining of big parts that used to require a much bigger machine.The standard equipment of the FS Series includes an automatic milling head that enables a great number of machining angles thanks to its 1º back turn and 2,5º front turn. This allows for the machining of more than 5 sides without having to move the part, which saves time and space and makes the work more dynamic.Its power and R.P.M. enables work in first rough milling operations and in part finish operations.