Injection moulding machines play cardinal role in plastic products manufacturing; whereas the first hand are the expensive ones, buying them as second hand machinery is highly beneficial a decision for the startup companies with low-budget.

There is huge scope for injection moulding machines in sectors such as automotive, medical, aerospace, consumer products, toys, etc. Additionally, these are used a lot in various other sectors that may inter alia include plumbing, packaging, and construction, etc. by the companies or professionals. Nevertheless, the injection moulding industry tend to cater the specific need from the before mentioned industries and for that reason evolved over the decades thanks to a large number of products that have been brought up.

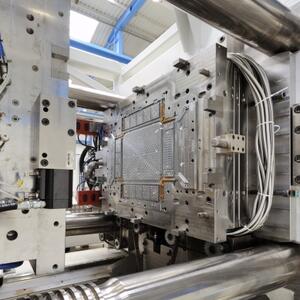

There are various names for injection moulding machines e.g. injection press and others; however, the fundamental use of such machines is to help in manufacturing the plastic products by contributing in injection moulding process. With two main parts e.g. an injection unit and a clamping unit, an injection moulding machine performs crucial role in plastic products manufacturing that are becoming popular a lot for the obvious reason that these are darn cheap and meet the specific requirement from the users.

Like any other machinery, here to depending upon the driving systems divisions are made in injection moulding machines; thus, there are hydraulic, mechanical, electric, or hybrid, etc. kinds of division in injection moulding machines. Buying them first hand is expensive and for that reason many companies, generally the ones that are new often buy the second hand or used ones. The multifold use of the injection moulding machines can be understood from the fact that these can fasten the mould both ways that is, horizontal or vertical.

Although there are several advantages that are associated with second hand machinery, the foremost is that these are available at darn cheap cost. Apart from the low-cost, the used machines are also attractive in the sense that these are tested and used and have track record of performing the job well. However, it is undoubtedly true that low cost is the single most reason for the clients who buy the used machineries. Nevertheless, buying second hand machinery can be right a decision if the same are bought directly from the seller; however, this is rare a case, as most of the companies hire the middle-man for the job.